The sector, led by the Eeltei Baylag Cooperative Network (EBCN), aims to improve fiber quality and breeding practices. Compliance with demanding specifications allows breeders to obtain certification, rewarding their environmental and collective efforts with a sustainability bonus .

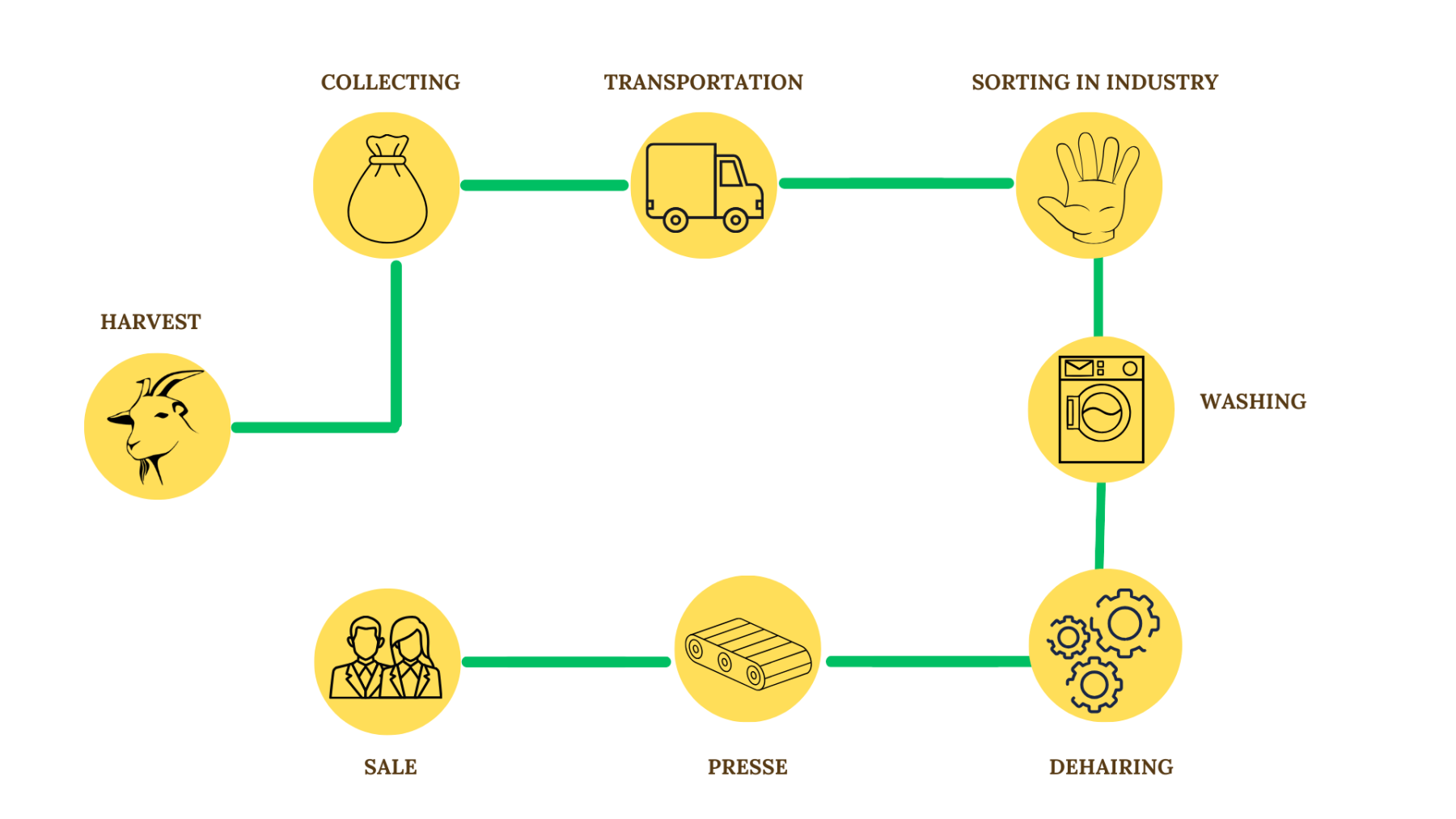

The production process

HARVEST . Combing is done goat by goat (the youngest are combed last in case of late bad weather), inside the yurt or under a stone-built structure. This shelter is necessary to avoid additional external dust. Combing the goats requires 3 types of comb to refine it, avoid dirt and optimize the quality of the harvest. Cashmere is harvested by breeders respecting the sorting by quality, sex, color and age. It is stored in approved bags to avoid any polluting materials (plastics, etc.).

COLLECTION. This takes place inside the shed in the presence of inspection staff. The cooperative’s technical team sorts the cashmere as farmers individually bring in their raw materials. Each farmer fills out a form, the Bag Sheet Form, with the following information: the number and name of the farmer who filled the bag, as well as significant criteria: weight, quality, certification level, and their signature. The cashmere is then placed in an approved bag and sealed until its arrival in the capital. It is during the collection process and based on the cashmere market price that the farmers are paid.

TRANSPORT. Each cooperative transports the cashmere by land to the first industrial processor in the capital, Ulaanbaatar. The codes for each bag are entered on the Transportation Sheet Form . The convoy is accompanied by a representative of the cooperative who countersigns the loading and unloading on the Transportation Sheet Form . The final reception of the bags at the factories in Ulaanbaatar is carried out by an EBCN representative for verification.

INDUSTRIAL SORTING. The representative of the cooperatives that accompanied the convoy participates in the industrial sorting and ensures that there is no mixing between the different types of cashmere. A before/after sorting report is carried out. The cashmere is sorted by hand by the workers then placed in sealed bags and stored in a secure location. The quality of the cashmere is noted on a form for feedback to the breeders. This sorting refines the two previous stages: harvesting and collection. This step requires concentration and patience to facilitate the industrial process that will follow.

WASHING. This is the first industrial process carried out by machines. It is carried out with water and soaps selected to be as natural as possible, in accordance with Mongolian standards. It removes soil, grease, and other impurities present in the raw material. The cashmere fibers are cleaned by color, without mixing.

DEHAIRING. This industrial step involves separating the coarse hairs—the husk—from the cashmere—the finer fiber—which will be spun to make clothing. The fiber passes from machine to machine, and the workers carry out this long transfer, in a gesture complementary to that of the machines. This step is carried out without mixing batches of different colors and qualities.

PRESS. Each batch of cashmere, clearly differentiated from one another, is brought to this final industrial stage. The unshorn cashmere is compressed and baled. These bales are numbered and hand-sewn with the sustainable and certified cashmere logo. The bales are then stored in a secure location awaiting exhibition.

SALE. It is carried out according to the contract established in advance with the various EBCN customers . Cashmere bales are delivered directly to national customers. For international customers, the bales are shipped by plane under the supervision of an EBCN representative, who takes care of customs clearance. Official documents such as the Bale Sheet Form are sent to customers and/or presented to customs if necessary.